-

Safety Products

safety-products

-

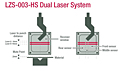

LZS-003-HS LazerSafe Hydraulic Press Brake Safety System

The LZS-003-HS press brake guarding system offers a highly effective solution for both operator safety and machine productivity. The LZS-003-HS system is Category 4 compliant and meets the world’s most demanding international safety standards.

The LZS-003-HS features a laser transmitter and receiver that are mounted on the upper beam of the press. Two continuous parallel flat-band lasers provide a 40mm protective zone directly below the punch, allowing the operator to remain close to the work piece as the tools close at high speed. If an obstruction is detected, the beam movement is stopped so that the punch cannot make contact with the obstruction.

The dual laser design is suitable for high speed press brakes with a fast closing speed of >150mm/s. As the tools close the bottom laser is muted just above the work piece triggering a deceleration of the machine to pressing speed while the top laser continues to provide protection until the tools enter the bending phase of the stroke.

The LZS-003-HS system is available as standard on new machines from leading press brake manufacturers, or as a retrofit for your existing machine. Contact your machinery dealer or your authorized Lazer Safe installer. - Superlight VI Programmable Safety Light Curtains

-

Cornering Mirror

Cornering Mirror

(9)Through the use of cornering mirrors, multiple sides or work envelopes can be guarded which enhance safety and reduce downtime related to mechanical and electrical interlock systems.

Include a 5% reflectivity loss per mirror when calculating total scanning distance of light curtain.

NOTE: Mirrors are surface coated. Wipe surface using only a damp, clean, soft 100% cotton cloth. To replace: remove the end bracket, slide out the mirror with the gasket. -

Pedestal (Model 8000)

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either the SuperLight VI system or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

Pedestals must be bolted to the floor, they must not be movable (ANSI B11.19-1990)- Sliding Mounts supplied

- Standard height - 72" (1829mm) - Model 8000

Optional height - 96" (2438mm) - Model 8096 - Painted OSHA yellow

- Pedestal - 12 gauge steel Base Plate - 1/4" (6mm) steel plate

-

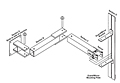

Model 9000 Swing Mount Brackets

Excellent method of mounting light guard for press brakes or when light guard is to be moved for die setups or machine maintenance. Model 9000 consists of three 180º pivot points along with light guard diagonal movement capability for virtually unlimited light guard positioning. Two-inch square tubing 3/16" (5mm) thick painted OSHA yellow which mounts directly onto the machine housing and makes for a heavy duty yet versatile mounting bracket.

Specify dimensions "B" & "C"

Ordering Procedure:

Specify Pedestal Model # and Quantity.- Specify Model 9000 Swing Mount Brackets and quantity.

- Specify B & C dimensions required.

- Specify light curtain or mirror size to be mounted.

Fab Supply is the master Distributor of the revolutionary

Rolla-V lower dies and is an excellent source for

light curtains, safety products, shear blades, urethane dies and accessories.